“The Domestic Way” - through disciplined process and uncompromising standards

We begin with listening, not assumptions. Every project is guided by experience, clear systems, and an insistence on getting the details right the first time. From design through installation, we rely on proven processes, disciplined execution, and thoughtful material choices to ensure each space functions beautifully and endures over time. We don’t rush decisions, cut corners, or follow trends for their own sake. The result is work that feels considered, refined, and built to last.

Step 1 - Design

Design is the foundation of everything we build. It’s where function, proportion, and material choices come together long before anything is fabricated. Thoughtful design ensures each space works effortlessly, feels balanced, and remains timeless rather than trend-driven. When design is done properly, the result isn’t just beautiful cabinetry—it’s a space that lives well and continues to feel right for years to come.

What this includes:

Initial consultation focused on lifestyle, function, and long-term use

Space planning and layout refinement for flow, proportion, and usability

Thoughtful material and finish selection guided by experience, not trends

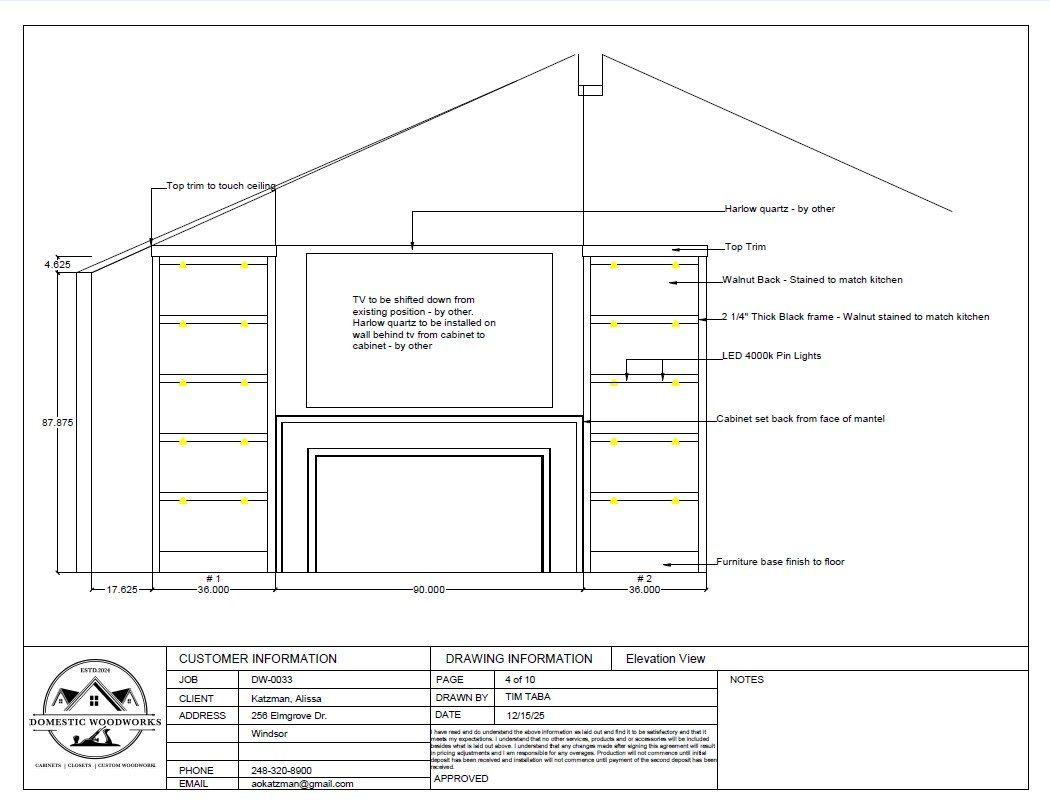

Detailed drawings and specifications that eliminate guesswork

Final design review to confirm clarity, expectations, and scope

Step 2 - The build

Manufacturing is where design intent is protected through precision and discipline. Every component is produced to exact specifications, with close attention paid to materials, tolerances, and finish quality. Our process is structured to minimize variables, maintain consistency, and respect the craft at every stage—from preparation through final assembly. Nothing moves forward until it meets the standard established at the design phase, ensuring the finished work reflects both accuracy and longevity.

What this includes:

Material preparation and component production to exact specifications

Careful finishing processes that prioritize durability and consistency

Controlled assembly to ensure accuracy and fit before installation

Quality checks at each stage to maintain the standard set in design

Our manufacturing process is built to protect quality, reduce variables, and deliver work that performs as intended.

Step 3 - Install

Installation is approached as a continuation of the craft, not a handoff. Each piece is placed with care, refined on site, and integrated seamlessly into the space it was designed for. Our team works methodically, respecting both the home and the design, ensuring alignments are precise and details are resolved properly. The result is cabinetry that feels considered and permanent—fitting the space as though it has always belonged there.

What this includes:

Site preparation and coordination to ensure a smooth install

Precise placement, leveling, and alignment of all components

On-site adjustments and refinements for a perfect fit

Final walkthrough to ensure every detail meets expectations

The goal is a finished space that feels intentional, refined, and seamlessly integrated into the home.

Every step of our process is intentional, from the first design conversation to the final installation. By relying on experience, clear systems, and uncompromising standards, we’re able to deliver work that feels cohesive, considered, and built to last. The result is not just beautiful cabinetry, but spaces that function effortlessly and stand the test of time.